UMIX has always valued our technical development since the

establishment of the company as a private management manufacturer. We have been

continuously searching for the cutting-edge technology with flexible ideas and the

latest facilities in the time.

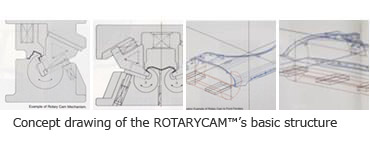

Based on this management principle, by supporting our technology, we have met our customers’ demands promptly and made the special structure as our world patented ROTARYCAM™, JCMCAM and our own unique products, press die standard parts.

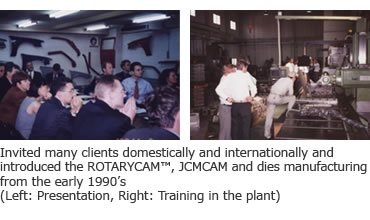

We established business relationships directly with worldwide foreign companies from the early stage; as a result our products have been implemented and supported by both our domestic and international customers.

In the USA, UMIX founded a die construction plant and promoted the local production. We strive to meet a diversifying market’s needs by improving the work productivity and shortening the lead time.

We retain our expertise by the extensive employee training and continuous self-improvement. It is also enhanced with the latest CAD/CAM/simulation systems, precision large machine/press facilities based on the ISO9001 quality policy and ISO14001 environmental policy.

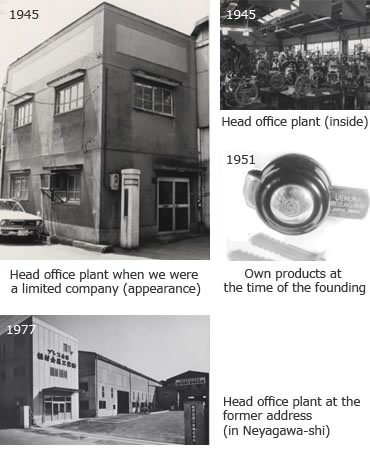

| 1945 | The first representative director founded UEMURA METAL DIE WORKS in Asahi-ku, Osaka as a private management die construction plant (manufactured dies and press dies of home device makers in Kansai) |

|---|---|

| 1951 | Obtained the patent of "Primary Combination Key" which was developed in-house |

| 1953 | Reorganized into Uemura Metal Die Works Limited |

| 1956 | Developed "Quick Shutdown Device of Crank Press" and applied for a patent (1966 obtained the patent) |

| 1961 | Started sales activities in the domestic automobile industry |

| 1967 | Reorganized into Uemura Metal Industries Co., Ltd. (Reconstructed the factory and installed a 200 Ton Press) and started receiving orders for automotive dies |

| 1977 | Due to sales growth & business expansion, the head office and plant were moved to Neyagawa-shi, Osaka |

| 1981 | Developed ROTARYCAM™ as an in-house exclusive product |

| 1982 | Constructed the precision machinery plant and installed several small precision NC finishing machines (by Mitsui Seiki and Makino), 500-Ton and 100-Ton presses (by Amino) and a large NC finishing machine (by Okuma) |

| 1984 | Constructed the machine plant next to the main factory |

| 1987 | Started exporting to Southeast Asia Started sales activities for the USA and European markets |

| 1988 | Started exporting to Europe |

| 1989 | Started exporting to the USA Obtained the patent for the ROTARYCAM™ in major industrialized countries as an exclusive in-house product |

| 1990 | Changed the company name to UMIX CO., LTD. |

| 1992 | Founded JCM CO., LTD. as a subsidiary of UMIX CO., LTD. which manufactured standard cams and dies components Installed a 1500-Ton press Promoted dies and exhibited own products at INTERMOLD (in Osaka) |

| 1993 | Began business relationships with Chrysler, General Motors (GM), Opel Promoted dies and exhibited own products at INTERMOLD (in Tokyo) |

| 1994 | Began business relationships with Audi AG, Daimler AG and Volvo Car Corporation |

| 1995 | Gave the lecture on our own products, ROTARYCAM™ and JCMCAM , at the request of VDI(the Association of German Engineers , conference at Dusseldorf) |

| 1997 | Began business relationships with Ford Motor Company (Germany) Attended VDI(the Association of German Engineers , conference at Dusseldorf) sectional meeting. |

| 1998 | Obtained the patent of "multiple ROTARYCAM™" in major industrialized countries as an exclusive in-house product |

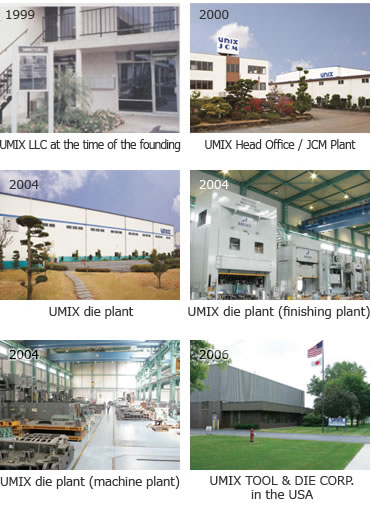

| 1999 | Founded UMIX LLC in the USA Began business relationships with BMW AG and Ford Motor Company (USA) |

| 2000 | Established the present UMIX head office in Hirakata-shi, Osaka Established the present JCM head office plant in Hirakata-shi, Osaka Both UMIX and JCM earned ISO 9001 certification |

| 2002 | Both UMIX and JCM earned ISO 14001 certification Gave the 2nd lecture on our own products, ROTARYCAM™ and JCMCAM, at the request of VDI (the Association of German Engineers, conference at Dusseldorf) |

| 2003 | Began business relationship with VOLKSWAGEN AG |

| 2004 | Opened the new die construction and tryout plant of UMIX in Hirakata-shi, Osaka Installed a 2500-Ton press and a large high speed 5 sided finishing machines |

| 2005 | Founded UMIX GmbH in Germany Added a large high-speed 5-sided finishing machines |

| 2006 | Founded die (ROTARYCAM™) construction plant in Michigan, USA and started local production Re-named as UMIX TOOL & DIE CORP. |

| 2007 | Installed an optical 3D scanner ATOS III |

| 2011 | Upgraded to ISO9001:2008 certification |

| 2013 | Expanded the line-up of our own products, UMIX unit cams and standard die components Renewed the homepage and the catalog |

| 2015 | Elected as one of the 300 Japanese "GANBARU" (vibrant) small and medium enterprises of 2015 by The Small and Medium Enterprise Agency of Japan |

| 2017 | Upgraded to ISO9001:2015 / ISO14001:2015 certification |