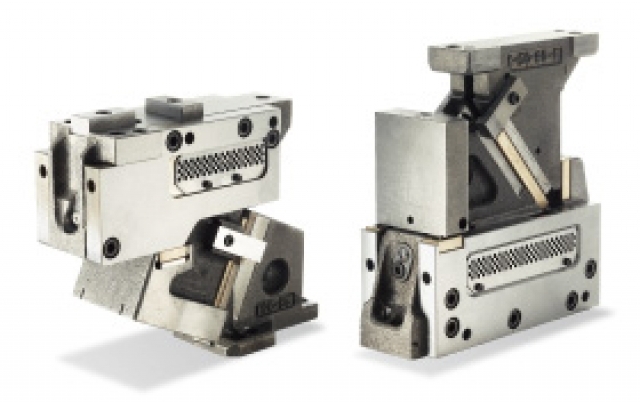

NZ1 series is designed to realize the compact and high performance cam by adopting polyhedral shape in the slide and setting the guide structure and gas springs within the working width. It also has an acceleration system, which greatly contributes to the press die rationalization and the noise reduction of stamping plant.

In addition to our existing regular type (RF), the following new models (TF/BF) are now available.

*The location of mounting screws/dowels remains the same among “NZ1-RF/TF/BF.” Therefore, depending on the circumstance, a cam can be interchanged to one in a different force, even after the completion of stamping die.

1. Improvement in Handling Procedure and Efficiency

The NZ1 cam series utilizes the guide pin (shaft) technology, which will maintain stability in the cam slide area and is easily inserted and removed (world patented). Therefore, it is easy to disassemble the slide cam from the cam base or in the die where the cam is placed/mounted (even in the press). This structure greatly reduces the disassembly/reassembly time and helps to improve efficiency at any stage of the process.

2. Improvement in Safety

Compared to a conventional type structure, the guide pin (shaft) enables the NZ1 cam to be more robust and stable, helping to improve cam safety. This guide pin (shaft) also contributes to sustain precision of cam slide when a cam travels directly.

3. Improvement in Durability and Stability

As its pressure source, the NZ1 cam series adopts built-in nitrogen gas springs. It also has 3 more characteristics: oil-less plate(s) on each upper/lower slide surface (double wear plates), V-shaped section at the bottom of slide surface, and low center of gravity. All of these features are designed to endure wear-out and uneven pressure, which leads to durability and stability.

4. Variety in Size

NZ1 cam series has the range of working surface width from 90mm to 400mm. UMIX cam series has a variety angles in 5-degree increments, from 0 to 75 degrees for aerial and from 0 to 25 degrees for die mount.

5. Data

Data is available in CATIA-V5, NX, STEP, DXF(2D), IGES(3D) and PDF (download free). Please visit our Members website (Free registration required).

NZ1 SERIES

NZ1-RF(Old Name : NZ1)

NZ1-TF

Return Force Enhancement

Keeping the same size as the "NZ1-RF", the "NZ1-TF," series enables the gas spring pressure for cam return to be approximately 2 times greater compared to the standard product "NZ1-RF."

"NZ1-TF" is now available for cam trim, pierce or flanging operations where cams require more return force.

*The location of mounting screws/dowels remains the same among “NZ1-RF/TF/BF.” Therefore, depending on the circumstance, a cam can be interchanged to one in a different force, even after the completion of stamping die.

Keeping the same size as the "NZ1-RF", the "NZ1-TF," series enables the gas spring pressure for cam return to be approximately 2 times greater compared to the standard product "NZ1-RF."

"NZ1-TF" is now available for cam trim, pierce or flanging operations where cams require more return force.

*The location of mounting screws/dowels remains the same among “NZ1-RF/TF/BF.” Therefore, depending on the circumstance, a cam can be interchanged to one in a different force, even after the completion of stamping die.

NZ1-BF

Return Force Enhancement + Heavy Duty

To reach the maximum return force within a limited size range, extra gas springs, which start traveling approximately 10mm prior to die closed position, are added to "NZ1-BF," while the ease of cam maintenance remains the same.

"NZ1-BF" is recommended for high-strength steel or aluminum, as these type materials have been increasing in the market recently and will continue in the future.

*The location of mounting screws/dowels remains the same among “NZ1-RF/TF/BF.” Therefore, depending on the circumstance, a cam can be interchanged to one in a different force, even after the completion of stamping die.

To reach the maximum return force within a limited size range, extra gas springs, which start traveling approximately 10mm prior to die closed position, are added to "NZ1-BF," while the ease of cam maintenance remains the same.

"NZ1-BF" is recommended for high-strength steel or aluminum, as these type materials have been increasing in the market recently and will continue in the future.

*The location of mounting screws/dowels remains the same among “NZ1-RF/TF/BF.” Therefore, depending on the circumstance, a cam can be interchanged to one in a different force, even after the completion of stamping die.